Which turning tools can be

|

||||

|

|

||||

|

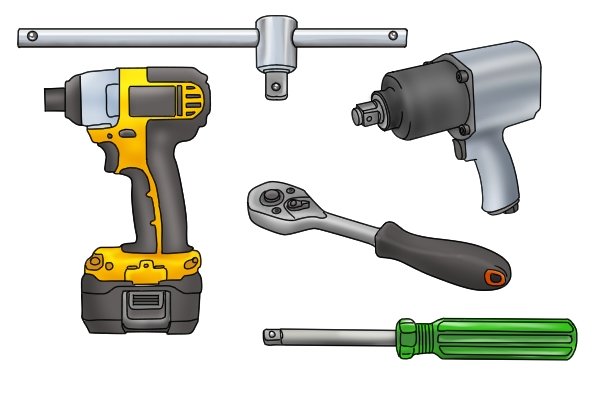

There are many different types of turning tool, each having benefits and drawbacks that make them more or less suitable for certain jobs. Although there are many varieties available for use with sockets, they can be separated out into two groups: manual and powered turning tools. | |||

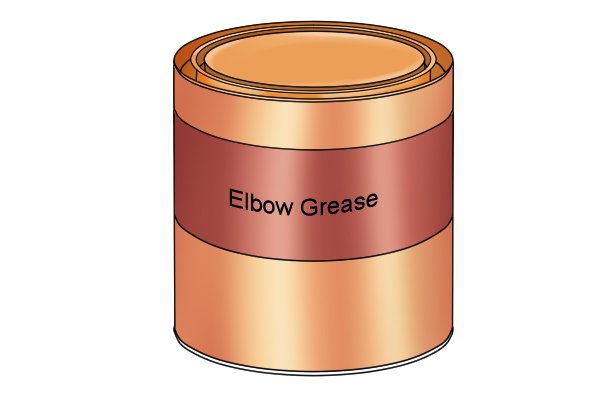

Manual turning tools |

||||

|

||||

|

Warning! elbow grease can sometime be in short supply. | |||

|

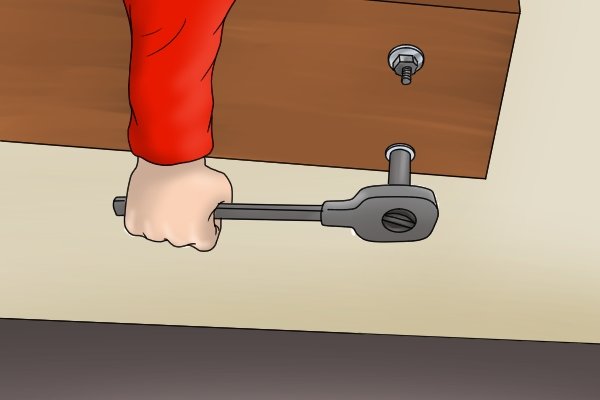

Ratchet wrenchesA ratchet wrench (often referred to as simply a ratchet) is the most common type of turning tool used with sockets. A ratchet has a square drive with a spring-loaded ball bearing for attaching to a socket. The ball bearing helps to keep the socket secured to the square drive by locating into the side hole of the socket driver. The reversible ratchet mechanism turns the socket in one direction only, whilst allowing the ratchet handle to move back in the other direction without turning the socket. |

|||

|

There is a lever or switch, usually on the head of the ratchet, to alter which direction it will allow the socket to be turned. This means the ratchet handle does not have to rotate a full circle to turn the socket.A ratchet can be used to quickly turn a socket in confined spaces where only a small degree of movement can be achieved with the handle of the turning tool. | |||

|

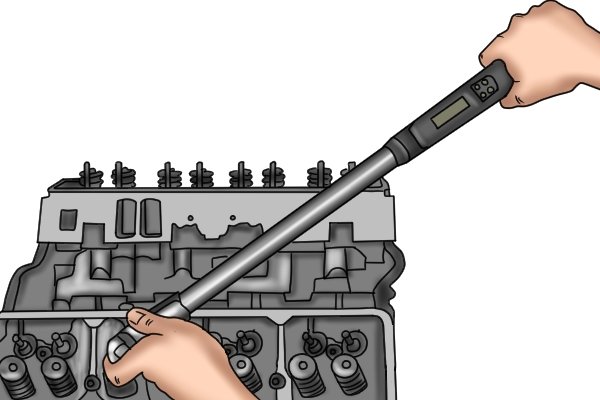

Torque wrenchesA torque wrench is a ratchet that can be set to only apply a certain amount of torque to a fastener. This prevents fasteners from being overtightened (required in some situations), the rounding of fastener heads, and the stripping of threads. It can also be used to ensure a fastener is tightened sufficiently to safely hold an object in place. |

|||

|

The amount of torque that is applied can be adjusted usually by a scale on the handle. When the desired torque is reached, the torque wrench will ‘click’ and not apply torque to the socket or fastener, informing the user that the specified torque has been reached. | |||

|

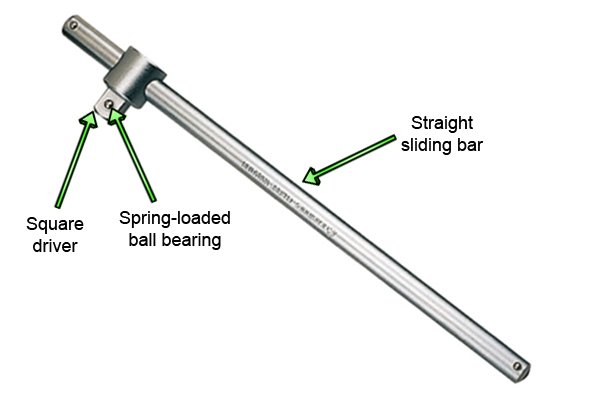

Sliding T-barsSliding T-bars are simple turning tools that have a square driver for attaching to a socket. A spring-loaded ball bearing on one face of the driver helps to keep the socket secured to the square driver by locating into the side hole of the socket drive. |

|||

|

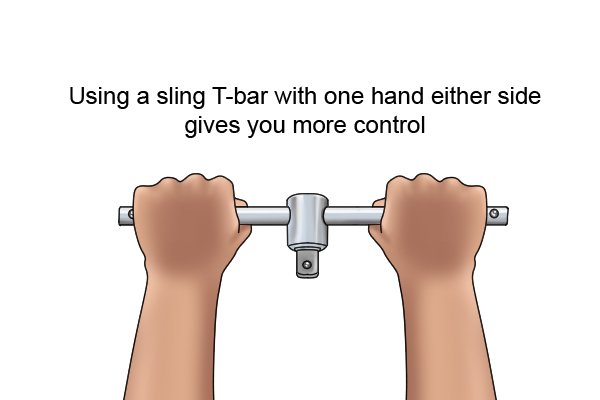

A sliding T-bar has a straight bar (Tommy bar) which allows you to use two hands to turn the socket, with one on each side of the bar when it is positioned centrally. | |||

|

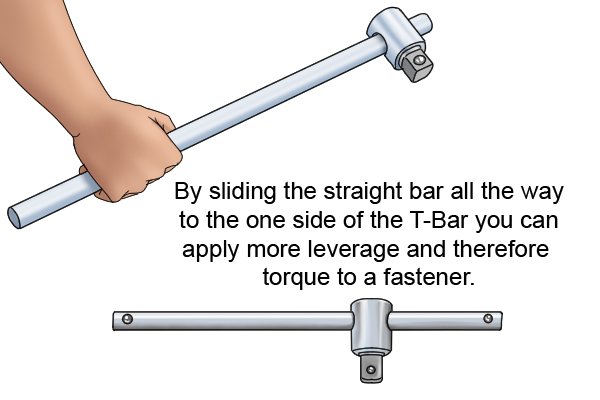

Or the bar can be slid all the way over to one side to give greater leverage and torque to the socket. The sliding bar can be moved from one side to the other if there are any obstructions preventing you from turning it all the way around in one complete circle.Sliding T-bars are available with ¼”, ⅜”, ½”, ¾” and 1″ drives. | |||

|

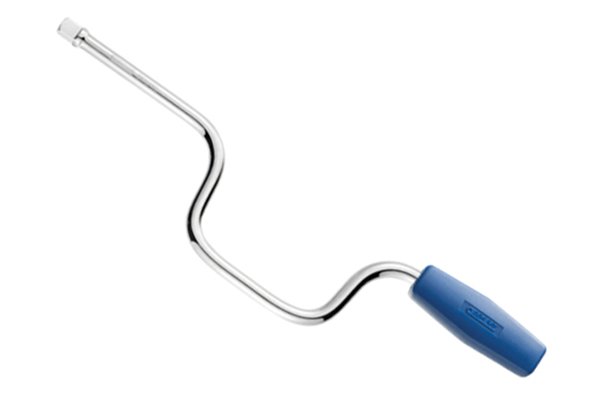

Speed bracesThese are often referred to under several other names including: speed handles, crank handles and speed wrenches. Like all socket turning tools, the speed brace has a square driver with a spring-loaded ball bearing that helps to keep the socket secured to the square driver by locating into the side hole of the socket drive. The handle at the end rotates freely around the shaft of the speed brace. |

|||

|

This allows the speed brace to be rotated very quickly, saving time and effort. However, the speed brace does have several drawbacks. It is long and therefore requires enough room to fit in and be turned. Also, it cannot apply very much torque so may require another turning tool to initially loosen the fastener. | |||

|

Speed braces used to be used a lot in automotive repair shops but are less frequently used now due to the increased use of impact wrenches. | |||

|

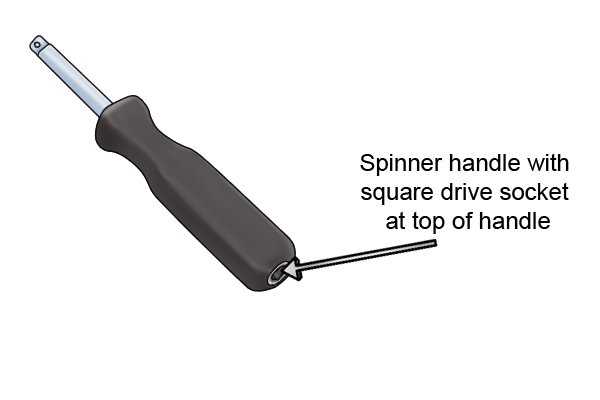

Spinner handlesA spinner handle is similar to a screwdriver but with a square driver in which to fit a socket. A spring-loaded ball bearing secures the socket to the square driver. Spinner handles are used mainly with small sockets as they allow fast turning of the socket, but cannot apply a lot of torque. |

|||

|

Some spinner handles will have a square drive socket at the top of the handle enabling a ratchet to be attached. This feature means more torque can then be applied to that fastener due to the increased leverage provided by the ratchet handle. | |||

|

You can use a spinner handle to quickly pinch up a nut or bolt and then connecting a ratchet will enable you to apply more torque to tighten it up. | |||

|

Spinner handles are often used in the assembly and repair of electronic equipment, and ones designed for this use will be sold as ESD safe. This stands for Electro Static Discharge. Spinner handles that are ESD safe will not discharge electrostatic energy that could damage electronic equipment. Spinner handles are available with ¼”, ⅜” and ½” drive sizes. | |||

|

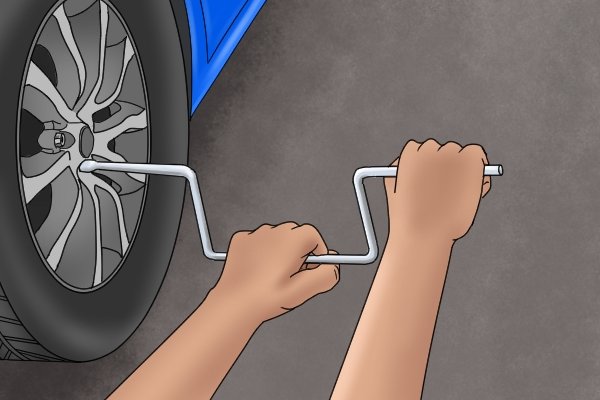

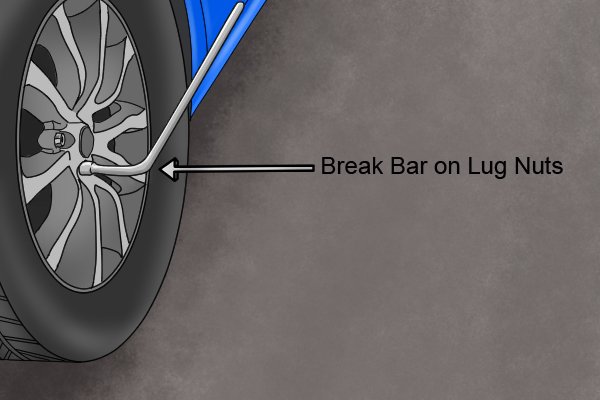

Power barsPower bars are also called breaker bars because they were originally used to break seized nuts or bolts in order to remove them. They can range in length from 230mm (9″) to over 600mm (24″) and have a joint just behind the drive square that allows the bar to articulate. |

|||

|

Once a nut or bolt has been initially freed up, the joint allows the bar to be straightened so the nut can be turned quicker. Power bars used to be used a lot in automotive repair shops but are less frequently used now due to the increased use of power impact drivers instead. | |||

Powered turning tools |

||||

|

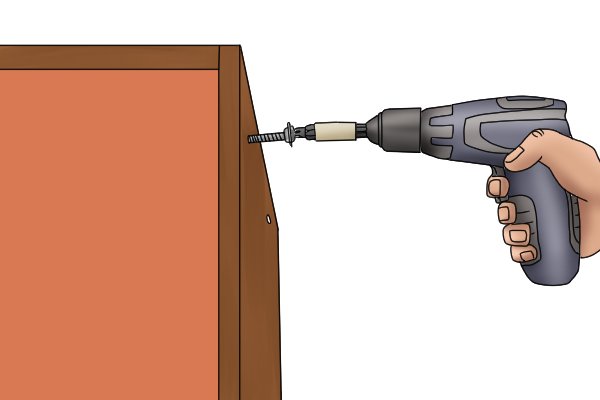

Powered turning tools can deliver more torque and tighten or loosen fasteners quicker than manual ones, but they are more expensive, often heavier, and can sometimes be too large for use in certain areas.Powered turning tools should only ever be used with sockets or screwdriver bits that are designed for use with power tools, such as impact sockets. | |||

|

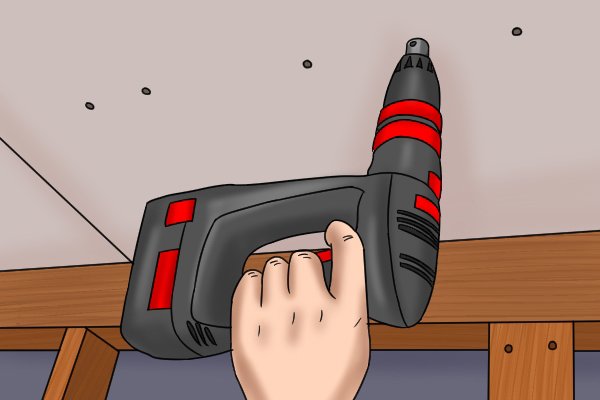

Electric drillsElectric drills can be either battery (cordless) or mains operated (240v or 110v). Connecting them to a socket or screwdriver bit will usually require the use of either a screwdriver bit holder or ‘hex to square drive’ adaptor that will need to be secured in the chuck of the drill. The socket or screwdriver bit is then fixed to the bit holder or adaptor. Drills allow sockets and screwdriver bits to turn fasteners very quickly, but they do have some drawbacks: |

|||

|

One of these disadvantages is that drills can be heavy and awkward to use in confined spaces. Also, unless the clutch is set low on the drill, it can kick back once the fastener is tightened up, and, if the clutch is set too low, it may not provide enough torque to tighten the fastener correctly.Because of these reasons, electric impact drivers are generally preferred for use with sockets these days. | |||

|

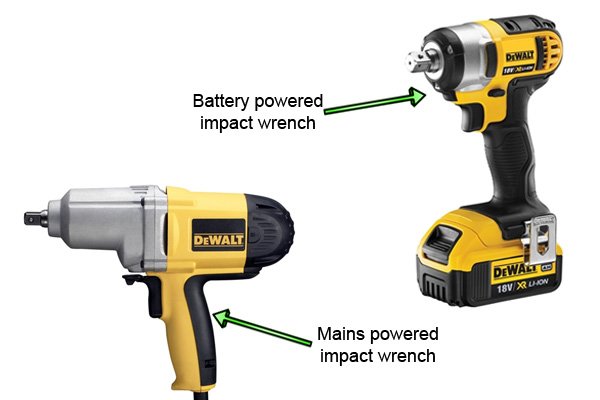

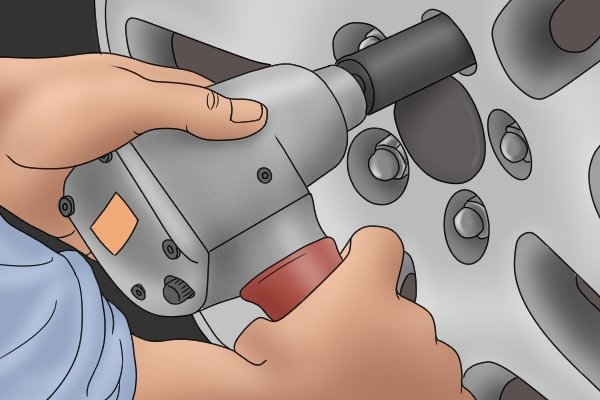

Electric impact wrenchesJust like an electric drill, an electric impact wrench can be either battery or mains-operated. Electric impact wrenches look very similar to electric drills but are often a bit smaller despite the fact that they actually deliver more torque through the use of the impact mechanism. |

|||

|

They have a drive square for use with impact sockets. The torque forces and vibration generated by the impact mechanism mean that you should only ever use specially designed impact sockets or screwdriver bits with this type of turning tool. | |||

|

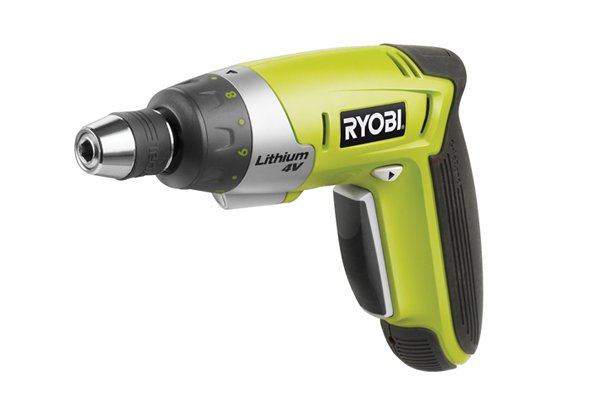

Electric screwdriversElectric screwdrivers are the smallest and lightest of the powered turning tools, weighing as little as 400g. Their light weight and compact size makes them handy for getting into confined spaces. Electric screwdrivers have either a magnetic or quick-release bit holder. |

|||

|

However, you will need a ‘hex to square drive’ adaptor if you want to use an electric screwdriver with a socket.Due to their small size and limited power, electric screwdrivers are not capable of delivering a lot of torque to a fastener in comparison with other powered turning tools. | |||

|

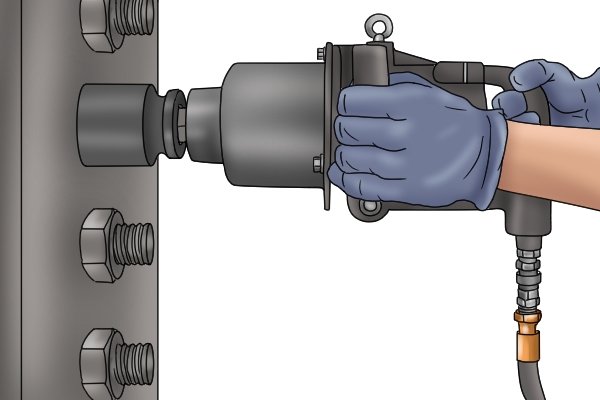

Pneumatic impact wrenchesPneumatic impact wrenches are powered by compressed air, so require an air compressor to work. As electric motors are larger than pneumatic motors, pneumatic impact wrenches can be made smaller than electric ones. Pneumatic impact wrenches are often more powerful than electric ones. |

|||

|

Pneumatic impact wrenches are mainly used to break loose or tighten fasteners very tight. They are not suitable for tightening fasteners that may require more control, as they can easily round fastener heads and strip threads due to the torque they provide. Pneumatic impact wrenches are commonly used in garages for vehicle repair and maintenance. | |||

|

Hydraulic impact wrenchesHydraulic impact wrenches are by far the largest and most powerful form of turning tool. They require a hydraulic compressor to power them. |

|||

|

They are capable of delivering more torque than any other impact wrench, but due to their cost, they are almost exclusively used in heavy industry and are considered specialist tools. Remember that different types of socket are suited for different tasks. | |||

Which turning tools are most commonly used with sockets? |

||||

|

Ratchets are the most common turning tool used with sockets as they are relatively cheap, require no additional power source, and are often supplied with a socket set itself. If you’re in the market for a new socket set then check out our Best Socket Set Review. | |||