What is a Hex Socket?

The term ‘hex socket’ refers to a socket that fits around the outside of a hexagonal fastener head. However, its use has broadened and it is now sometimes used to refer to any shape of socket that fits around the outside of a fastener, instead of locating into the fastener head.

6 Point Hex Sockets

A ‘hex socket’ is a socket designed to fit the head of a hexagonal fastener such as a nut or bolt.

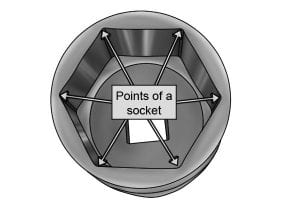

Hex sockets are also referred to as ‘6 point’ sockets as six points are formed where the internal walls from the hexagonal recess meet.

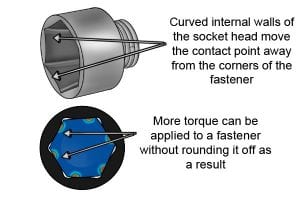

Better quality hex sockets have internal walls that are slightly curved. This helps apply the torque from the socket to the flats of the fastener instead of the corners, which reduces the chance of rounding the head of the fastener.

This also means that more torque can be safely applied to the fastener by the socket, allowing them to be tightened more or screwed into harder materials such as metal or hard woods.

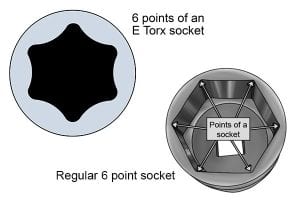

What is meant by regular 6 point?

When a socket is referred to as being a “regular 6 point” it means it is a 6 point hex socket. This term is sometimes used to avoid confusion with E Torx sockets that also have 6 points.

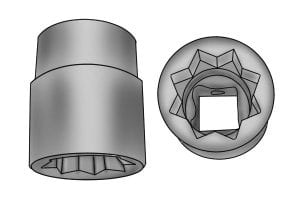

12 point bi-hex sockets

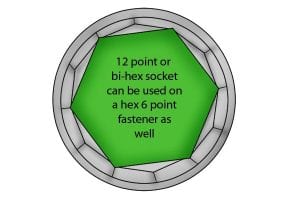

A ‘bi-hex’ or ‘bi-hexagon’ socket is also called a 12 point socket. This is because twelve points are formed where the internal walls of the recesses intersect.

The name ‘bi-hex’ comes from the internal shape of the socket recess being that of two hexagons laid over one another.

Just like ‘hex sockets’, ‘bi-hex’ sockets can also be used to tighten or loosen hexagonal shaped fasteners, but they have a couple of advantages:

They are able to fit 6 point fastener heads in twice as many positions as a regular ‘hex socket’. This means it is easier to locate the socket onto the fastener in tight spaces.

They can also be used to turn square (4 point) and bi-hex (12 point) fastener heads as well, giving them greater versatility.

The bi-hex shape allows the socket to fit over the head of squares fasteners, unlike a regular hex socket.

However, a bi-hex socket will apply the torque closer to the corners of a 6 point hex head fastener, which means the chances of the fastener head becoming rounded are greater.

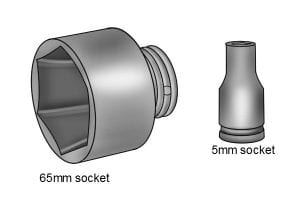

Hex Socket Sizes

Socket Head

Socket heads can be measured in both metric and imperial units. Metric socket sizes can range from 3mm to over 80mm, while imperial socket sizes range from 5/32″ to over 1-½”.

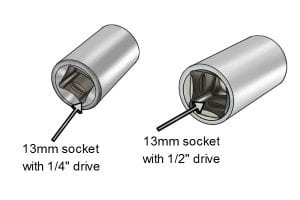

Drive Socket

At the other end of the socket is the drive socket, which is used to attach the socket to a ratchet, torque wrench or other type of turning tool.

Unlike the head of hex and bi-hex sockets, which is available in both metric and imperial sizes, the drive socket is always sized in imperial measurements. The most common sizes are ¼”, ⅜”, ½”, ¾” and 1″.

Other Types of Hex Socket

With the increasing variety of sockets, the term “hex socket” is often used to describe any socket that fits over the head of a fastener instead of fitting into the fastener head, as with a socket bit. This is despite many of these new forms not having a hexagon shape to them.

Other sockets exist too, see What are the different types of socket? to find out more!

8 point and square sockets

Whilst it still may be possible to get an 8 point or square socket, they are now considered a specialist item that is often only made to order in the size you specify, as 12 point sockets will usually be able to do the same job.

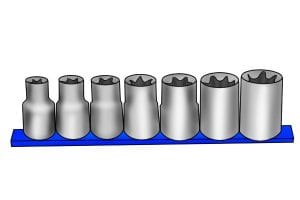

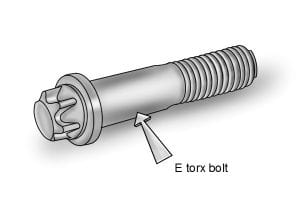

E Torx Sockets

E Torx, or ‘external Torx sockets’ to give their full name, are sockets designed to fit and turn fasteners with an external Torx head.

E Torx sockets are sized from E1 (smallest) to E100 (largest), although most E Torx socket sets will range in size from E4 – E24. Like standard sockets, they have a square drive for attaching a turning tool that can range from ¼” – 1″ in size.

E Torx sockets and fasteners can apply more torque than regular hex or bi-hex sockets without damaging the fastener head.

This is because of the greater contact area between the socket and the fastener head, along with the fact that more of the torque is applied away from the corners of the fastener head, so there is less chance of it rounding off.

E Torx are often used in areas where high torque and clamping force is required.

One of the most common places to find E Torx fasteners is on the cylinder head bolts of car engines.