What are the different types of socket?

There are many different types of socket available, each differing in terms of the fastener they are designed to be used on, or the turning tool they can be used with.

Examples include the hex socket that is designed to turn nuts and bolts, E Torx sockets for E Torx bolts and pass through sockets for use with a pass through ratchet.

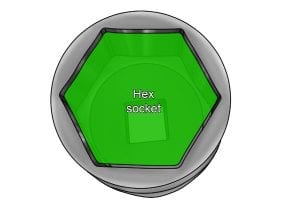

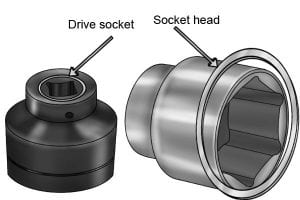

Hex Sockets

Hex sockets are the most common type of socket and come in two main types: hex/6 point sockets and bi-hex/12 point sockets.

Hex sockets have a square drive socket at one end, used to attach them to a turning tool such as a ratchet, and a hexagonal or bi-hexagonal recessed socket head at the other end used to turn fasteners such as nuts and bolts.

For more detailed information about hex sockets see our page: What is a hex socket?

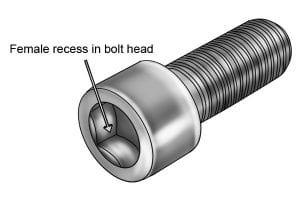

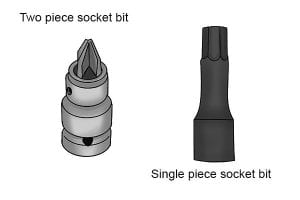

Socket Bits

Socket bits are a combination of a screwdriver bit and a hex socket. They can either be made of one solid piece of metal, or constructed from two separate parts that are then fixed together.

All socket bits connect to a turning tool like a ratchet in the same manner as a hex socket, using a square drive. The other end of the socket bit fits into the correspondingly-shaped female recess on the fastener head.

One piece socket bits will have a screwdriver bit permanently attached to their opposite end, or will have their body shape moulded in the shape of a driver bit (see Driver – A driver, in reference to a socket, is the object that is doing the turning. So a socket itself can be the driver when talking about tightening a bolt, or a ratchet could be the driver when talking about the turning tool used to turn the socket).

Two piece socket bits consist of a socket body (which looks like a regular socket) and a removable driver bit, held in place by a grub screw. Socket bits come in a huge variety of shapes, and each one is designed for a particular style of fastener head.

For more detailed information on socket bits see our page: What is a socket bit?

Impact Socket

Impact sockets are designed for use with impact drivers such as air guns, which are able to deliver a much greater torque than ordinary drivers and wrenches, as well as producing more vibration from the impact action.

Impact sockets are made from a more ductile and less brittle grade of steel that is designed to cope with this higher torque and impact vibration, which may cause an ordinary socket to shatter. Impact sockets are a different colour to other sockets as they have a different surface coating.

This difference in appearance helps to identify which sockets are suitable for use with impact drivers and which are not.

For more detailed information, see our page: What is an impact socket?

Spark Plug Socket

Spark plug sockets are used to fit or remove spark plugs from engines. They will often have a foam rubber insert that sits inside the socket, which serves to help hold the spark plug snugly, and prevents it from being damaged against the socket’s internal walls. They come in sizes: 16mm, 18mm, 21mm, 5/8″ and 13/16″.

Make sure you always use the correct size spark plug socket for your car. Using the wrong size or an imperial size spark plug socket on a metric spark plug or vice versa is likely to damage the spark plug and could make it impossible to remove.

See What is a spark plug socket? for more information.

Insulated Sockets

Insulated sockets have a coating on them to insulate them from electrical current. This coating will often be in two layers of different colours – usually red and yellow. Insulated sockets are tested to a safe live working current, for both an AC and DC electrical current.

Insulated sockets should only be used as part of an insulated socket set, which will contain an insulated turning tool. This is because the sockets themselves will not provide safe insulation from electrical currents, unless they are also used with other insulated tools such as insulated ratchets.

For more information see What is an insulated socket?

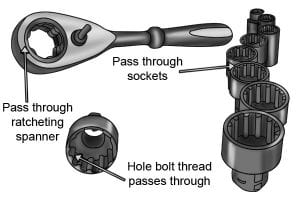

Pass Through Sockets

Pass through sockets do not have a square drive socket like other sockets. Instead they are designed to be turned by a ratchet spanner that fits over the top of the socket.

The socket is hollow, which enables long bolts to pass all the way through it and the hole in the ratchet spanner, whilst the socket head fits onto the nut. This means pass through sockets can sometimes be used to remove or replace nuts on very long bolts that even a deep socket cannot reach.

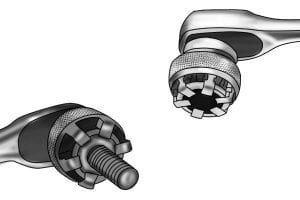

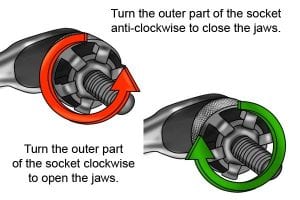

Adjustable Multi Sockets

Adjustable multi-sockets have jaws which can be adjusted to fit fasteners of many different sizes. This means that one socket can do the job of many differently sized sockets. These sockets help to prevent the rounding of fastener corners by distributing an equal force on all sides of the fastener.

This is done by making contact with the fastener head on the flats instead of the corners. They can be adjusted to fit odd size or rounded fasteners that other sockets wont. Multi-sockets are adjusted by rotating the outer part of the socket, which moves the jaws in and out, so they can clamp around the head of a fastener.

Twist the head of the multi-socket anti-clockwise to close the jaws or clockwise to open them. Adjustable multi-sockets do have a few disadvantages. They are not available in as many drive socket sizes as other sockets so you may have to use a larger or smaller turning tool with them than you would ideally like.

Also, when adjusted for small fasteners, the outer diameter of the socket remains the same size as it is when adjusted for larger diameter fasteners, so it may be too large for use in tight spaces.

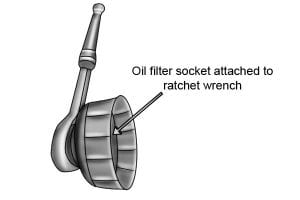

Oil Filter Socket

Oil filter sockets are large, shallow sockets designed to fit and remove oil filters from vehicles. Oil filter sockets will often have a much thinner wall thickness than other sockets of a similar size, because they do not need to withstand high torque forces, as oil filters often only have a plastic thread, that will not allow the filter to be over tightened.

For more information see What is an oil filter socket?

Universal Socket

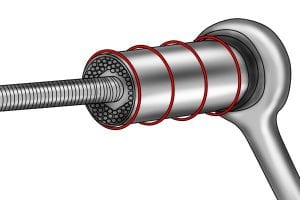

Universal sockets have lots of spring-loaded pins within the socket head. As the socket is placed over the head of a fastener, the pins in contact with the fastener head are depressed, leaving the remaining pins to surround and grip the fastener head.

This design allows universal sockets to fit many different sizes and fastener head designs, as well as enabling it to turn damaged fastener heads in some cases. However, the pins inside the socket head do not depress very far so the universal socket is only able to grip the top of a fasteners head.

For more information see What is a universal socket?

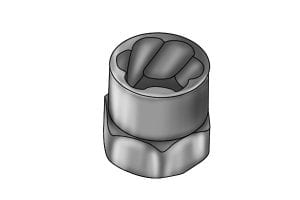

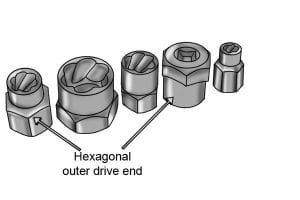

Bolt Grip Sockets

Bolt grip sockets are designed solely to remove seized, corroded or damaged fasteners, they are not used to tighten fasteners. The internal walls of the bolt grip socket are concave with a reverse spiral flute design. This allows the socket to fit most types of fastener head.

The edges of the reverse spiral flute design dig into the metal of the fastener head, giving a tight grip which enables the socket to remove seized, corroded, painted or damaged fasteners. Bolt grip sockets are sold as a set of five sockets. Sizes range from 8mm – 19mm (5/16″ – 3/4″).

The way in which they are designed to bite into a bolt head, gives bolt grip sockets the unique ability among non adjustable sockets of being able to be used on both metric and imperial fasteners. They have a 3/8″ square drive for attaching them to a turning tool such as a ratchet, but also a hexagonal outer shape to the drive end of the socket.

This allows a spanner or adjustable spanner to be used with them if you do not have a ratchet. Apart from being designed to turn fasteners anti-clockwise only to loosen them, bolt grip sockets are used in exactly the same way as standard sockets.

See How to use a socket with a ratchet wrench for more information.